Capstone instructor

The 2024 Senior Capstone course in chemical engineering was taught by Chuck Coronella. To learn more about the chemical engineering projects, please email Chuck Coronella.

About the department

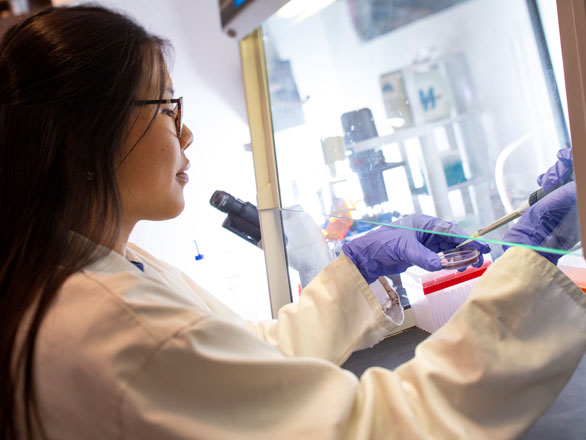

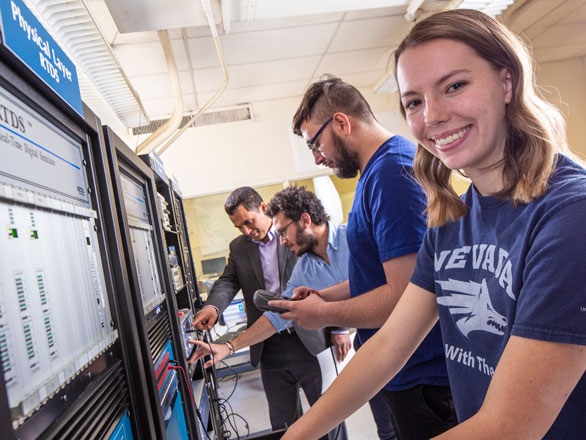

Our undergraduate programs offer you the opportunity to work closely with our research-active faculty. Small class sizes and undergraduate research opportunities help you get to know your professors and provide opportunities to get hands-on research experience. We offer Nevada's only undergraduate degree program in chemical engineering and materials science and engineering. Visit the Department of Chemical & Materials Science Engineering.