Chemical & Materials Engineering Assistant Professor Yufeng Zheng will begin research this August to design novel titanium alloys with both high strength and ductility (capability of materials to bend and stretch without breaking). His work potentially will impact the design of novel lightweight advanced alloys for the aerospace and automobile industries as well as advance the electron microscopy education for the University students with hands-on experience.

The five-year project is funded with a $520,583 National Science Foundation CAREER award Zheng received earlier this year. CAREER awards are the NSF’s most prestigious award recognizing early-career faculty who have the potential to serve as academic role models in research and education and to lead advances in the mission of their department or organization. Zheng’s CAREER project, “Understanding the Role of Nanoprecipitates in Advanced Metastable Titanium Alloys,” seeks to design novel titanium alloys using a new designing strategy called metastability engineering.

“I will use metastable titanium alloys (titanium combined with other metal elements and in an intermediate energy stage) as an example to study the critical issues in metastability engineering,” Zheng said.

Metastability engineering, as Zheng explains it, is a new concept in designing advanced metal alloys that can overcome the trade-off between strength and ductility. Zheng specifically is studying the internal connections between the configuration of atoms in the nano-scale region in the titanium alloys and the responses of these alloys to different external environments (such as different temperatures or load conditions) using the University’s cutting-edge electron microscopes.

It’s all about the titanium alloys

Titanium alloys —lightweight but strong, making them an ideal material for the aerospace and automobile industries — seem to be Zheng’s material of choice: he received another NSF grant back in 2021 to research different compositions of titanium alloys, including the use of alloying elements that cost less than those currently in use, as well as looking for strategies to manufacture titanium alloys at room temperature (another way to save costs on manufacturing).

This time, Zheng is looking at titanium alloys as a way to investigate the new metastability engineering concept. As he phrases it:

“In the metastability engineering, the bulk stability of alloys is tailored by tuning their compositions to promote plastic deformation via strain-induced transformation as well as other hardening mechanisms, such as precipitation hardening and solid solution hardening, and thus achieve the combination of excellent strength and ductility.”

And this is where the nanoprecipitates — small precipitates undetectable by the human eye — come in. Zheng’s CAREER award project, “Understanding the Role of Nanoprecipitates in Advanced Metastable Titanium Alloys,” involves looking at different metastable nanoprecipitates that form in titanium alloys, especially the nanoscale O’ phase, a new phase found and reported by Zheng for the first time in the world. As Zheng puts it:

“These metastable nanoprecipitates can alter the composition and structure in the local nanoscale region, and thus tailor the local stability in metastable titanium alloys and enable the activation of phase transformations that are spatially confined only to the nanoscale metastable regions.”

What isn’t fully understood, Zheng said, is the intrinsic correlation between the metastable nanoprecipitates, local stability and the enabled confined phase transformation and deformation in metastable titanium alloys.

“To fully understand the mechanisms that account for the synergetic high strength and ductility of metastable titanium alloys, there is a critical scientific need for a comprehensive understanding of the role of the nanoprecipitates, like O’ phase, in these alloys,” Zheng said.

Zheng adds that the information gathered from this study of titanium alloys could be applied to other advanced metallic materials, such as metastable steels and metastable high-entropy alloys.

Small world

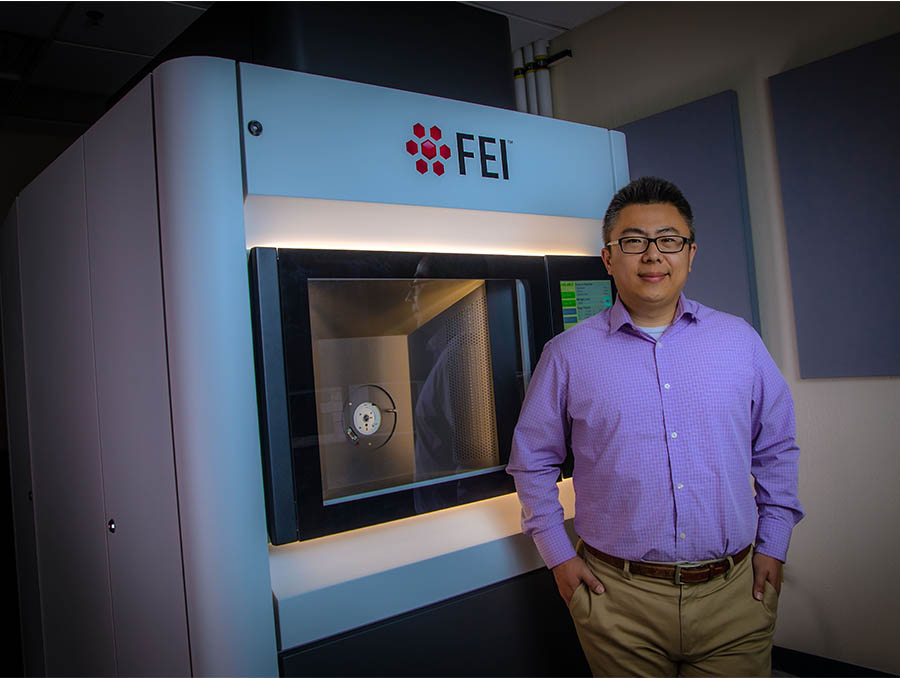

Electron microscopes play a big part in Zheng’s work: he is the interim director for the College of Engineering’s Electron Microscopy and Microanalysis Facility, which houses the remote transmission electron microscope operation system and the portable desktop scanning electron microscope. These electron microscopes are critical in the field of materials science and engineering, allowing researchers to study the interrelationships of materials processing, structure and property at micro- and nano-scale.

They’re also important for students.

“Using the microscopes in the classroom can help create a student-centered learning environment, stimulate students’ interests in materials science based on what they observe, and thus serve as an important strategy toward the inquiry- and case-based instruction in the materials science education,” Zheng says.

As part of his CAREER project, he plans to design new electron microscopy education modules for graduate and undergraduate students at the University, as well as outreach activities for K-12 students in the Reno community.

At the end of the five-year project, Zheng’s work could also impact industry. Titanium alloys with high strength and good ductility could improve the manufacturing of lightweight aircraft for better fuel efficiency and reduced CO2 emission, Zheng predicts, among other industry applications.

Zheng credits the support he has received from the Department of Chemical and Materials Engineering, the College of Engineering and Research and Innovation for his success, as well as his students, including Ph.D. student Dian Li; colleagues; collaborators and friends.