A RETROSPECTIVE ON AN UNPRECEDENTED YEAR

Last year, when the world entered an unprecedented lockdown to slow the spread of COVID-19, students and faculty in the College of Engineering got to work.

Last year, when the world entered an unprecedented lockdown to slow the spread of COVID-19, students and faculty in the College of Engineering got to work.

In March 2020, higher education around the world changed. Classrooms were closed, the lights turned off, and everyone went home to finish out the semester via Zoom, wondering what would come next. From their home offices, living rooms, and garages, though, the faculty and staff in the College of Engineering at the University of Nevada, Reno immediately got to work helping the community.

“Engineers address the world’s most pressing problems,” College of Engineering Dean Manos Maragakis said. “Overnight, the ways we worked and collaborated changed, and every member of the College immediately adopted new methods to continue to meet the needs of our students. In the face of the challenges presented by the pandemic, our students, faculty and staff harnessed their skills and used the resources available to them to help in every way they could. I am proud of their contributions to our global community.”

April 8, 2020

When the pandemic began, one of the first challenges facing the world was the lack of a sufficient supply of personal protective equipment. Meanwhile, campus makerspaces and 3D printers were dormant. Faculty, students and staff members in the College began putting their resources to good use by 3D printing personal protective equipment such as face masks and NIH-approved face visors.

Among those working on the project were Associate Professor of Computer Science and Engineering David Feil-Seifer and K-12 Outreach Coordinator Clair Parker. But as Feil-Seifer was quick to point out at the time, their contributions were part of a larger community effort.

“Members of the Reno community started this effort,” Feil-Seifer said. “We are working with people on campus, local businesses and individuals in town to see what was wanted that we could make, and how much. They did the hard work of making those contacts and let us know where it was needed and if the medical community would accept the equipment.”

Within three weeks, Feil-Seifer was producing 40 visors a day and had secured material for 3,000 shields from department offices. By April 19, 2020, the community-wide effort had produced 5,607 pieces of personal protective equipment for distribution to local hospitals and medical facilities.

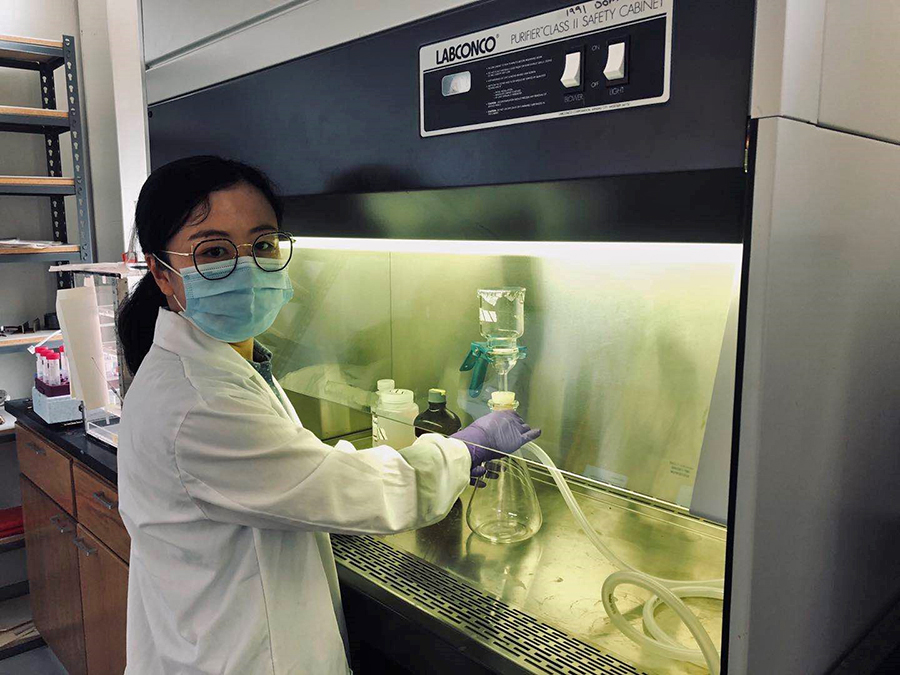

Department of Civil & Environmental Engineering graduate student Lauren Mazurowski working in the William N. Pennington Engineering Building on the Nevada Water Innovation Institute's COVID-19 monitoring project.

August 20, 2020

Based in the College of Engineering, the Nevada Water Innovation Institute joined regional agency partners to provide a new way to monitor our progress in the fight against COVID-19. Recognizing that wastewater from affected persons leaves a viral signature that can be identified through analysis well ahead of a positive test, Krishna Pagilla, director or the Nevada Water Innovation Institute and Ralph E. and Rose A. Hoeper Professor and Chair of the Department of Civil & Environmental Engineering, spearheaded an initiative to provide the community with the ability to predict outbreaks.

When the work was announced in August, Pagilla explained: “My research group has been collecting wastewater samples since May at the three water reclamation facilities in the region to measure the viral signatures (an inactive RNA fragment of the SARS-CoV-2 virus) of COVID-19 which allows us to determine the presence of COVID-19 in the community as well potentially tell us about community prevalence. The main goal of this research is to conduct environmental surveillance of wastewater at the water reclamation facilities and in the collection systems by monitoring of SARS-COV-2 marker during the pandemic in the Truckee Meadows region,” Pagilla said.

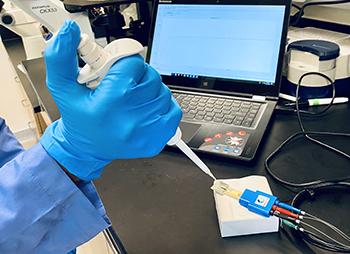

Med School Research Scientist Timsy Uppal and College of Engineering post-doctoral researcher Bhaskar Vadlamani testing a SARS-CoV-2 nanosensor. A collaboration between UNR Med and the laboratory of Department of Chemical and Materials Engineering Professor Mano Misra, the nanosensor can provide results in 30 seconds.

October 13, 2020

In October, Department of Chemical and Materials Science Engineering Professor Mano Misra’s lab saw successful results for a SARS-CoV-2 test that provides results in 30 seconds. The test uses a nanotube-based electrochemical biosensor, a similar technology that Misra has used in the past for detecting tuberculosis and colorectal cancer as well as detection of biomarkers for food safety.

Misra has been working on nano-sensors for 10 years, and he brought to bear his expertise in detecting a specific biomarker in tuberculosis patients’ breath using a metal functionalized nano sensor to this challenge.

“I thought that similar technology can be used to detect the SARS-CoV-2 virus, which is a folded protein,” Misra said. “This is Point of Care testing to assess the exposure to COVID-19. We do not need a laboratory setting or trained health care workers to administer the test. Electrochemical biosensors are advantageous for sensing purposes as they are sensitive, accurate and simple.”

Instead of a blood sample, the test is run using a nasal swab or even exhaled breath, which has biomarkers of COVID-19. Misra and his team have successfully demonstrated the simple, inexpensive, rapid and non-invasive diagnostic platform has the potential to effectively detect the SARS-CoV-2 virus.

The team includes Associate Professor Subhash Verma, virologist, and Research Scientist Timsy Uppal at the University’s School of Medicine, and Misra’s post-doctoral researcher Bhaskar Vadlamani.

November 2, 2020

Although we have all become familiar with the ubiquitous rendering of the SARS-CoV-2 virus particle that results in COVID-19—a spherical center with spikes, called peplomers—there is still much for us to learn about the physical properties of the particle to deepen our understanding of how it works. Researchers in the Department of Mechanical Engineering, working with a team from Queen’s University in Canada (Mona Kanso and Jourdain Piette), recently published a study on the fundamental questions, “What, precisely, is the shape of the virus particle, how does it move, and how do these facts affect how it attacks?”

“The shape of the coronavirus was not exactly known,” Associate Professor James Hanna explained. “We knew it was roughly spherical, covered by a membrane, with a range in its number of spikes.”

While the world was in lockdown last year, Hanna worked with then Visiting Professor Jeffrey Giacomin of Queen’s University. The Tier 1 Canada Research Chair in Rheology, Giacomin brought his expertise on the flow properties of fluids to bear on the problem, while Hanna analyzed the geometry of increasingly complex viruses, culminating in the SARS-CoV-2 virus particle.

“Viruses have interesting geometry,” Hanna explained. “Using the fact that the spikes seem to be attached to a fatty membrane, free to float around under mutual repulsion, we began to work on a first principles baseline to understand the virus. What we found is a plausible idea of what the shape of the virus would be.”

Understanding the shape of the virus particle more deeply—as well as the locations of its peplomers—sheds some light on the importance of the way the virus moves. Instead of propelling itself, the virus particle is moved by a process called rotational diffusivity—a movement that is provoked by its thermal environment.

Giacomin explained, “The virus particle relies on the temperature of the particles surrounding it to move—to cause it to rotate about its center, to jitter.”

When it jitters, the virus particle has an opportunity to attach to a target cell via one of its peplomers. But this is where the story of the coronavirus particle becomes more complex. On the one hand, the number of peplomers the virus particle has affects its rotational diffusivity, and on the other, one spike attacking a cell is insufficient.

“When it is jittering around its centers, two adjacent spikes must attach to a target cell,” Giacomin said. “If it jitters too slowly, it will take too long to align the second spike.”

In other words, to attach to and attack a target cell, the external conditions and viral particle itself must have conditions that are just so. It has to be moving, but not too fast or too slow, and it needs to have spikes close enough to work in coordination.

“We don’t think the number of spikes on the coronavirus is happenstance,” Giacomin concluded. “Its number of spikes may give it just the right rotational diffusivity to do its job.”

The original research can be accessed freely from Physics of Fluids.

Aditya Nair with his students Mehar Mangat and Paul Remneff in the new William N. Pennington Engineering Building. Nair's work helped local authorities refine a COVID Risk Meter designed to help hospitals attain appropriate staffing levels.

December 8, 2020

When faced with the challenges associated with the coronavirus pandemic, a group of elected officials, doctors, medical professionals, data scientists, and public relations specialists from across the Truckee Meadows region developed the Truckee Meadows COVID Risk Meter. Based on five data indicators, the meter provides a daily assessment of the current coronavirus threat level, along with behavioral recommendations to reduce continued spread. Now, with the help of Assistant Professor Aditya Nair of the Department of Mechanical Engineering, the Risk Meter will be able to predict the threat level in the next seven to ten days. The new predictive capabilities will allow the community to prepare for surges and will have a particularly powerful impact on the medical community.

“Our job is to say what the data will look like seven days from now so that hospitals can anticipate their staffing needs. The predictive capability will allow us to make sure we have the bandwidth to handle more cases.... And the more data we have, the better the model will perform.”

Using a model called Sparse Identification of Nonlinear Dynamics (SINDY)—developed by University of Washington Professor Steven Brunton and collaborators—Nair has been able to analyze months’ worth of data in five key areas: Risk assessment, test positivity, daily new cases, hospital beds, and ICU use. The model allows Nair to make several refinements to the risk meter to turn past data into predictions for the future.

“With time as a determinate, the SINDY model finds weights to assign to the data indicators,” Nair said. “Not only that, it finds how the different variables interact, so if two factors reliably predict future threat, the model will weight those two variables more when seen rising (or falling) together.”

Doctoral student Nikhil Dhabarde tuning the anodization apparatus in the materials engineering lab. (Photo by Isaac Hoops)

February 12, 2021

Research to control and mitigate SARS-CoV-2 particles that linger on surfaces has shown that titanium oxide coated materials subjected to ultraviolet light can be highly effective in killing the virus.

“Our work indicates that surfaces protected with a well-known photoresponsive oxide coating serve as effective deterrent to the proliferation of COVID-19 surrogates,” Ravi Subramanian, a chemical and materials science engineering associate professor developing the new technology at the University, said. “We use a relatively common material called titanium dioxide (found in some toothpastes for example), but prepared in the form of nanotubes, along with UV light as the key agents to destroy the viral particles.”

A surface can be protected by applying the titanium oxide in several ways, and by illuminating the surfaces with a moderate source of UVC light. Studies were conducted with a closely related virus to SARS-CoV-2, as a surrogate of COVID-19, which was inactivated from the titanium oxide coated surfaces following a brief exposure of UVC light. Not only are the viral particles destroyed in a few seconds, they also found out that viral inactivation efficacy of these surfaces is retained even after multiple exposures, with similar results.

March 23, 2021

John Martini, assistant city manager for the City of Sparks, and Krishna Pagilla, Ralph E. and Rose A. Hoeper Professor and Chair of the Department of Civil & Environmental Engineering, discuss the results of the COVID-19 wastewater monitoring project Pagilla spearheaded.

While students and faculty pursued new research and harnessed resources to help slow the spread SARS-CoV-2, every aspect of the operations in the College of Engineering changed. While each member of the College has found new ways to work and capturing all of the changes from the past year would be impossible, here are some highlights of ways that the College continued to meet its goal of supporting the community it serves.

College of Engineering sponsored summer camps embrace new virtual format.

The William N. Pennington Engineering Building opens via virtual ceremony.

College of Engineering outreach programs go online.

College of Engineering Career Services connects students to employers through virtual information sessions

Former Secretary of the Department of Homeland Security (DHS) delivered a virtual Distinguished Lecture Series address titled “Homeland Security Challenges in the Age of Covid.”

To abide by gathering limits and to protect the health and safety of its employees, Sierra Nevada Corporation canceled its holiday parties and year-end meetings. Instead, they donated the holiday party funds to support a variety of local nonprofits, including the College of Engineering.

The Society of Women Engineers hosted the Evening with Industry event virtually.

The virtual Spring Internship & Career Fair connected 47 employers with 454 students through 642 one-on-one meetings.

The College of Engineering's Innovation Day became a virtual event. One hundred five teams of graduating engineering students shared their senior capstone projects and presented lightning talks.

The stories of the students and faculty in the College of Engineering who are making a world of difference through their research, outreach and service.