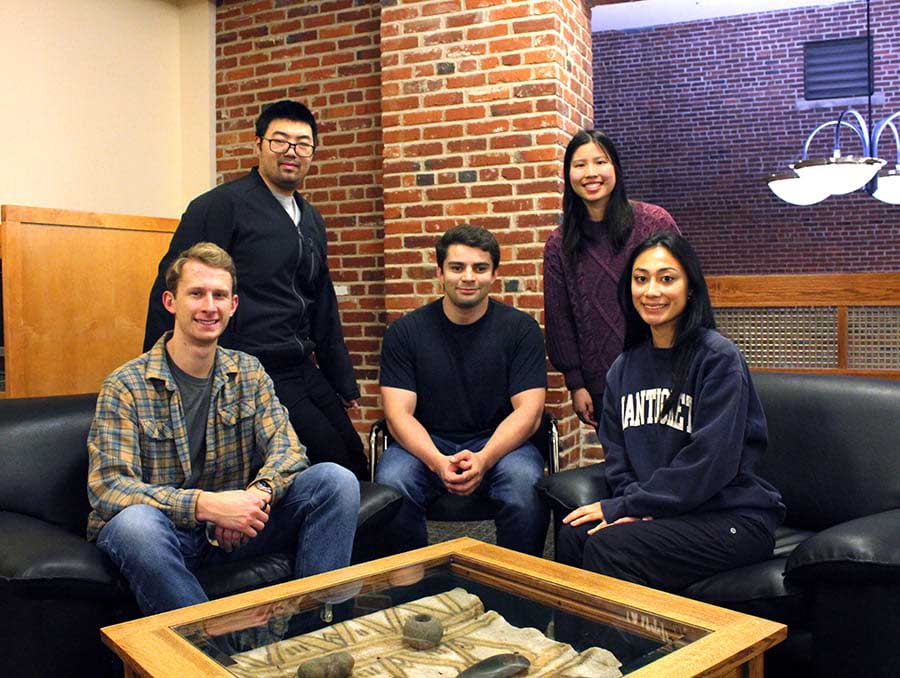

Five engineering students with plans and ideas that could benefit NASA’s mission to explore space are in the latest cohort of Nevada NASA fellowship and scholarship recipients.

Materials science graduate student Joy Calhoun and mechanical engineering graduate student John Crosby have received fellowships; mechanical engineering senior Liam Bond, electrical engineering senior Calvin Lu and mechanical engineering graduate student Shanti Quinto have received scholarships.

“This gives them the chance to have real financial support for their own ideas,” Research Professor Eric Wilcox, the statewide director for the Nevada NASA Space Grant Consortium and NASA EPSCoR programs, said.

The engineering students join 10 other University of Nevada, Reno and University of Nevada, Las Vegas students in the 2025-2026 cohort. The Nevada Space Grant fellowships can be up to $20,000 for the academic year, and the scholarships up to $3,000.

3D printing parts for rockets

Materials Science graduate student Joy Calhoun will be 3D-printing and testing metal and ceramic parts to determine if they are suitable for use in high-powered rocket motors reaching space.

“We’re (looking at) 3D printing things because we can make things very light and hopefully save the amount of material needed to create an object,” Calhoun said.

Calhoun, mentored by Professor Mano Misra, is creating metal parts using a process called fused filament fabrication (FFF), which prints a filament of metal powder with a polylactic acid (PLA) binder. Not all metal parts made through this process will perform the same, because each metal has its own melting point and other characteristics. But Calhoun thinks one thing might be the same: the pattern of pores, or tiny air pockets, inside the 3D-printed parts. Pores matter because they affect the strength and other characteristics of the final metal part. If the pore patterns turn out to be similar across different metals, that could help engineers better predict how a 3D-printed part made out of a particular metal will perform.

“The big goal,” Calhoun said, “is to help future engineers with small budgets confidently use FFF-printed parts in high temperature, high stress situations by making them more predictable.”

Developing materials to manage heat in space

Mechanical Engineering graduate student John Crosby’s research has focused on graphene and graphite, carbon-based materials that conduct heat well. For his Nevada NASA project, he’s looking at how graphene and graphite can be incorporated into wax-based phase change materials (PCMs) — materials that can store and release heat efficiently by melting and solidifying. PCMs already are used to control temperature on spacecraft and satellites, which are exposed to severe temperature swings in space, but Crosby’s work could help NASA improve their viability by finding ways to maximize their thermal conductivity and long-term stability. His mentor for the project is Associate Professor Yan Wang.

Crosby plans to pursue a doctoral degree in mechanical engineering and expand his research into the thermal engineering applications of nanofluids.

“After graduating,” he said, “I hope to work in the research and development of transformative thermal management technologies, with applications in fields such as supercomputing, clean energy generation and aerospace.”

New robotic arm for space applications

Mechanical Engineering major Liam Bond is developing a novel type of robotic arm for space applications. This robotic arm sets itself apart by having protected centralized motors and continuous 360-degree rotation as well as being lightweight and manufacturable through 3D-printing technology. Bond, who expects to earn his bachelor’s degree this fall, plans on pursuing a master’s degree in mechanical engineering. Eventually, he hopes to work in the aerospace and defense industries or in the area of sustainability. His project mentor is Assistant Professor Yifei Jin.

Collecting data on other planets

Electrical Engineering major Calvin Lu is working on a modular sensor platform, the Integrated Climate & Environmental Reader (ICE-R), designed to collect environmental data in harsh planetary environments. The system may include sensors for radiation, atmospheric gases and subsurface water or ice, depending on where it is deployed. Lu’s mentor for the project is Professor Jeongwon Park.

Embedded systems and environmental sensing are particular academic interests, and Lu recently completed a project on a sensor for early detection of wildfires. He has passed the Fundamentals of Engineering (FE) exam, the first step toward becoming a licensed professional engineer, and holds a Federal Aviation Administration remote pilot license. He is a member of the University’s Roller Coaster Club.

Lu expects to graduate this spring and hopes to eventually work in quantum electronics, a field of electronics that studies and uses quantum-mechanical effects to control and manipulate electrons and photons in devices.

“It’s new and interesting,” he said. “I just want to be a part of it.”

Expanding technology that benefits life on Earth and in space

Mechanical Engineering graduate student Shanti Quinto has always been interested in biotechnology and materials science, topics that have led her to 3D bioprinting research with Assistant Professor Yifei Jin. Her work focuses on embedded 3D bioprinting, where cells are printed inside a gel-like material so the printed structures don’t collapse. Conducting this work in microgravity environments — environments with near-zero gravity, similar to what astronauts experience in space — has potential for tissue and organ reconstruction because microgravity allows printed structures to maintain shape without being pulled by gravity, among other benefits.

Not only could this benefit life on Earth, but also people on future deep space missions.

“I have always admired NASA’s mission to expand and develop technology that benefits both life on Earth and in space,” Quinto said.