Led by the University of Nevada, Nevada Tech Hub announces the award of $15.5M in funding across 17 projects aimed to strengthen Nevada’s position in the national lithium battery and critical materials supply chain. These strategic investments advance Nevada Tech Hub’s mission to grow and onshore every segment of the lithium battery ecosystem – from education and workforce development to innovation and domestic supply chain research. Together, these projects represent a major step toward building a resilient, future-ready energy economy and reduced reliance on foreign supply chains.

“Our team has spent the past year diligently listening to leaders in the lithium battery and critical minerals industry, learning what they need to be successful, not just in terms of workforce, but across all aspects of the business,” Dick Bartholet, regional innovation officer for Nevada Tech Hub, said. “We’re proud to announce this impressive list of projects and partnerships that we are confident will support Nevada’s lithium and critical minerals economy and help secure a more reliable and domestic supply chain.”

Nevada Tech Hub is one of 31 Tech Hubs nationwide designated by the Economic Development Administration (E.D.A.) as playing a key role in a critical technology focus area. Over the past year, Nevada Tech Hub has met with industry partners and workforce development leaders to identify gaps and opportunities for funding, finding partners to provide solutions and crafting programs that solve problems in real time. The projects funded are:

Great Basin College was awarded $1.98 million to support the college’s new Industrial Tech Center in Winnemucca. The new facility provides a space for necessary programs that will fill the need for trained workers in the lithium battery and critical minerals economy. Opened in August, the Industrial Tech Center is anticipated, through spring of 2029, to train and credential approximately 250 new diesel technologists, industrial maintenance technologists, electrical systems technologists and instrumentation technologists for careers in the lithium battery supply chain.

Governor’s Office of Economic Development (GOED) received $497,420 to support the Individual Career Mapping (ICM) 3D Classroom Project, which uses virtual reality and immersive training to provide career exploration, science, technology, engineering and math (STEM) education and industry-recognized credentials with hands-on, industry-led training.

Dragonfly Energy, a Reno-based lithium battery manufacturer, was awarded $278,583 to upgrade and modernize its production systems, boosting the company’s efficiency, supporting workforce development and expand its production capacity. The project aims to improve the company’s operational efficiency by enhancing data collection, product transport and overall output. By leveraging existing partnerships with other Nevada Tech Hub consortium members, including Aqua Metals, Redwood Materials and Ioneer, Dragonfly Energy’s battery manufacturing capability plays a major role in the state’s circular battery supply chain.

Lyten, lithium-sulfur battery manufacturer, received $400,000 to advance the company’s proprietary Lithium Processing System (LPS) to a pilot-ready design. The proposed system uses ion-selective membranes to extract lithium from brines into a high-purity lithium carbonate equivalent without acids, bases, or waste, resulting in high lithium recovery with very little energy usage. The system is fully enclosed within a shipping container, making it safe and scalable. The technology will provide an environmentally safe and scalable way to extract lithium from difficult brines like those found in Clayton Valley, Nevada.

Manufacture Nevada received $199,120 to provide dedicated expertise to help Nevada Tech Hub companies secure resources needed to succeed and expand, including finding domestic suppliers of equipment and materials.

Nevada Bureau of Mines and Geology was awarded $140,000 to fund an assessment of Nevada’s historical and active mining sites to identify and quantify concentrations of target critical minerals such as cobalt, nickel, manganese and others in mine tailings or retrievable as by-products of existing mining operations. These critical minerals are often present in current mining operations but historically, due to their value or quantity, may not have justified the cost of a complete mining operation on their own. By identifying highly prospective deposits for potential extraction in existing operations, this project provides the necessary data for processing companies to attract investment, apply technology effectively and secure the minerals.

Nevada Department of Corrections was awarded $415,070 to expand re-entry programs for offenders, with career education and training specific to the lithium battery and critical minerals industry.

Nevadaworks, the local workforce development board for northern Nevada, was awarded $2.8 million to lead efforts aligning workforce initiatives with industry needs, including hiring a lead career navigator to head up the work in the lithium battery space. Nevadaworks was awarded an additional $215,000 to head up a statewide marketing campaign promoting Nevada’s jobs in the clean energy industry.

Northern Nevada Building & Construction Trades Council received $1.5 million to expand apprenticeship program capacity by adding key leadership positions including a director of recruitment and a building trades recruiter. These roles will strengthen apprenticeship recruitment and connect more Nevadans to careers.

Northern Nevada Central Labor Council and Northern Nevada Member Assistance Program were awarded $2.4 million to provide additional critical support services to apprentices in need, including financial assistance for boots, tools, equipment and transportation, as well as food and vouchers for housing and utilities.

Office of Workforce Innovation (OWINN) was awarded $219,999 to expand the Nevada P-20 to Workforce Research Data System (NPWR), unlocking new avenues of research, improving performance reporting and strengthening the link between workforce programs and long-term outcomes.

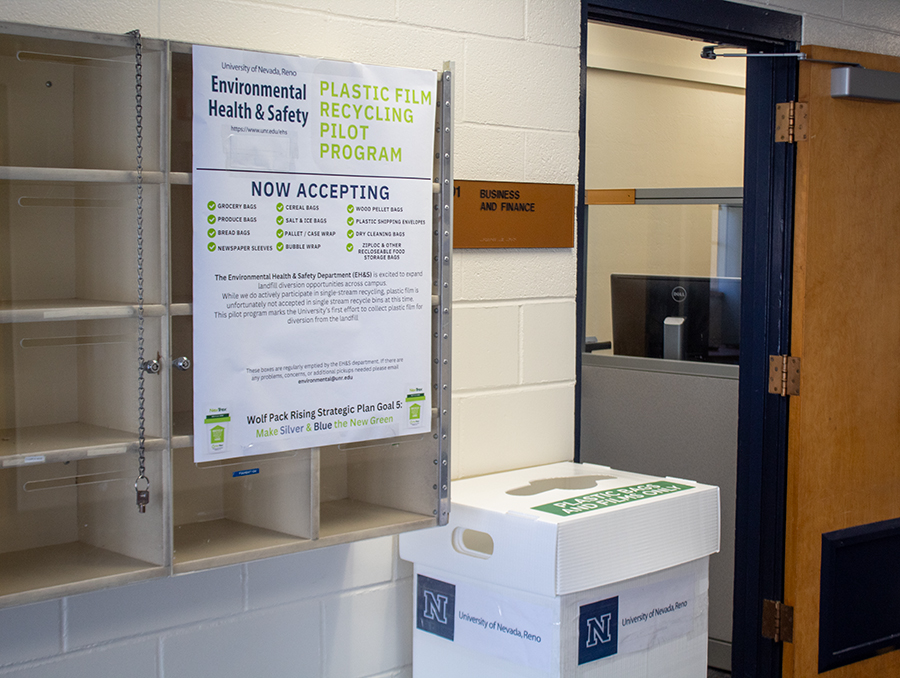

Redwood Materials received $440,890 to support a state-wide lithium battery recycling initiative. A collaboration with Washoe County, the project includes the deployment of 20 lithium battery-specific smart bins and a public education campaign to encourage responsible battery disposal, reduce landfill contamination and lower the risk of battery-related fires in homes and businesses.

Truckee Meadows Community College (TMCC) was awarded $1.8 million to expand its Advanced Manufacturing program, including the launch of a new Skilled Machine Technician registered apprenticeship program, featuring a 12-credit curriculum designed in direct collaboration with local industry partners. The funding also supports expanded faculty and lab staff, the purchase of advanced training equipment, and provides for participant support including registration and instructional materials.

University of Nevada Career Studios received $200,000 to develop and expand internship programs with partners in the lithium battery and critical materials industry.

University of Nevada College of Business was awarded $90,000 to support the development of a Workforce Readiness Bootcamp, offering students and recent graduates a dedicated, weeklong course to develop soft skills and emotional intelligence skills, something commonly identified by industry partners as a skillset that was lacking in new hires.

Western Nevada College (WNC) was awarded $1.8 million to support a new specialized training program to prepare workers for battery disassembly and recycling processes. This program, in collaboration with a strategic industry partner, will address the need for Nevada’s growing demand for skilled labor in the lithium battery recycling sector.

“Each of these projects plays an important role in the battery supply chain in Nevada,” Bartholet said. “From being responsible and smart about how we find critical minerals in Nevada to training the workforce that will be out there doing the labor, Nevada Tech Hub is working to ensure all elements of the battery supply chain are getting support when possible. This is a full-spectrum initiative, and we believe these projects each provide an important element to our overall success.”