Research conducted by Civil Engineering Professor Keri Ryan and her team last May is advancing the relatively new field of non-structural earthquake engineering. The team’s work was part of a multi-university and industry project that has been recognized by Engineering News Record, one of the construction industry’s most authoritative publications, as one of the 2023 Top 25 Newsmakers. The Top 25 Newsmakers list was announced Jan. 25.

The Natural Hazards Engineering Research Infrastructure (NHERI) TallWood project, led by Shiling Pei of the Colorado School of Mines and conducted at the University of California San Diego, examined the earthquake resilience of tall timber buildings — where the main structural components are made of layers of wood bonded together. A 10-story mass timber building constructed for the TallWood project underwent 88 simulated earthquakes to test new construction designs to increase earthquake resiliency as well as industry products. To date, this is the world’s tallest full-scale building ever tested on an earthquake shake table.

Advancing the earthquake resilience of non-structural systems

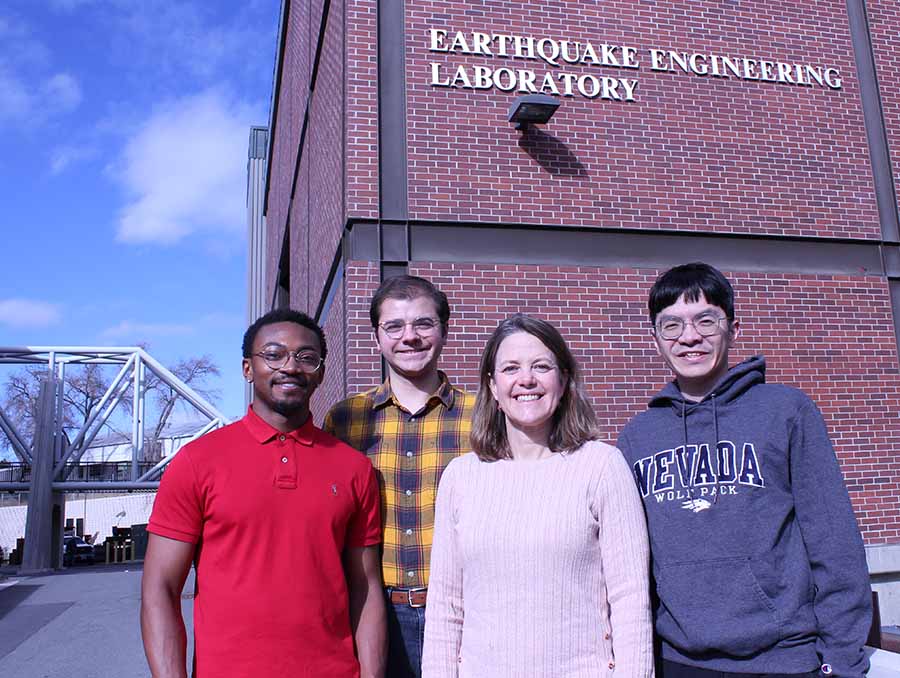

Ryan and her team — Ph.D. students Yi-En Ji, William Roser and Sir Lathan Wynn — studied the performance of non-structural components in the TallWood project, specifically interior walls and exterior facades.

“Structural design (which ensures the stability, strength and overall integrity of a building) is usually the focus, and looking at non-structural elements like this is a … less developed field,” Roser said.

Yet non-structural elements such as interior walls, stairs, elevators, plumbing, electric and ventilation systems, can be highly damaged during an earthquake, which affects whether or not a building is safe to occupy post-quake.

Addressing the need for more research in this area, each student focused on a particular non-structural element: Ji researched a ‘slip track’ design for cold-formed steel (CFS) framed walls, in which the top of the wall is not directly connected to the above floor slab, allowing the wall to move independently of the floor above; Roser focused on a different type of CFS-framed façade that is attached to the outside of the floor slab with sliding clips, and Wynn investigated a new type of fire-rated exterior glass curtain wall (exterior facade that supports glass panels) that is much stiffer and heavier than a typical curtain wall. The students had a significant role in the design drawings and calculations for these systems.

Ji said the slip tracks worked well and could reduce wall damage in an earthquake. The team continues to evaluate why some of slip tracks moved more than others, with the hope that their conclusions could help improve future designs.

Roser commented that sliding clips overall improved earthquake resiliency by preventing wall damage and that lessons learned from this project will help incorporate this technology into future designs.

Wynn reported that the curtain wall performed well with only minimal damage and no glass breakage. The curtain wall was able to successfully accommodate movement by allowing the glass panels to rotate within the framing.

Each student plans to publish two or three papers on their findings in peer-reviewed journals as well as present those findings at industry conferences and meetings. They also will try to get the information out to industry trade groups — such as cold-formed steel, fenestration and window manufacturers — who often handle the non-structural components of a building.