As the community celebrates 10 years of the Innevation Center, the University of Nevada, Reno is spotlighting the people and ideas that have shaped its vibrant community.

Below, former Innevation Center resident and member Joe Hill answers questions about innovation, entrepreneurship and the impact the center had on him.

My name is Joe, and I am the CEO/one of the founders at Adaract. We provide custom microhydraulic devices (tiny valves, pumps, actuators, etc.) for prosthetics, robotics and some industrial applications. While Adaract originally started as a personal project, all of our team is excited to enhance the mobility of amputees with the components we provide.

Outside of work, I spend most of my time making or working on stuff. Being able to make custom parts for old cars and trucks, vintage machinery (just restored an old Cincinnati T&C Grinder), and other projects has always been a lot of fun, so prototyping-heavy R&D is something I naturally enjoy.

Early involvement

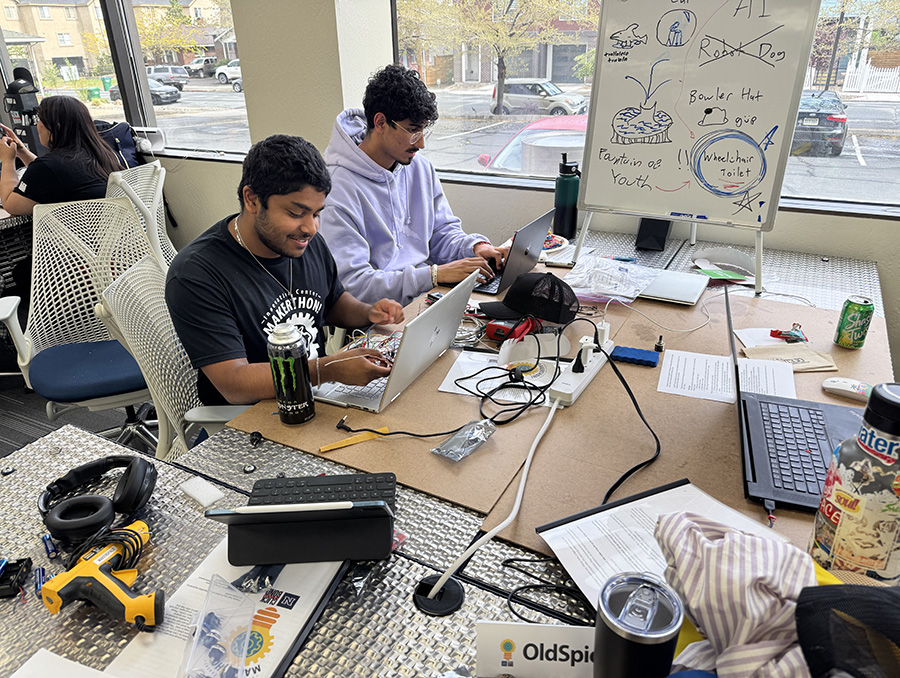

As a University mechanical engineering student, I toured the Innevation Center as a part of a club. It immediately seemed like a great place to work on all kinds of DIY projects, and I actually started out making some simple brackets on the Tormach mill for a friend’s project car.

"The Innevation Center was a great space to start in for early prototyping."

Adaract took the path of personal project to capstone project at the University of Nevada, Reno to startup, so the Innevation Center was a great space to start in for early prototyping. The Innevation Center staff was always friendly, helpful and patient, so it was a wonderful environment to work in.

We started out primarily working on hydraulically driven McKibben Muscles, so getting the first few demonstrations working with them was a lot of fun. If I remember right, we got one of muscles to last for 100,000 cycles at ~2,000 psi, which was an exciting milestone at the time. Making something “useful-ish” from raw materials was very rewarding.

Accomplishments supported by the Innevation Center

On the business side, the obvious answer is raising money from Angel investors to be able to work at Adaract full-time and grow the business. On the technical side, becoming fairly proficient at machining was something I was happy with. The fact that I could make just about anything I could think of (or at least, within the limits of the machines at the IC) was very exciting.

We had a lot of help in finding grant funding for prosthetics development through resources at the Innevation Center (namely EDAWN). This eventually led us to find our first major customer in the prosthetics industry.

It shaped all three (a project that became a startup, which will likely direct the path of my career until I retire). I was able to find work that I genuinely enjoy, so I plan to keep doing it for the next few decades. Without the IC, I would still be working in manufacturing at a factory - fine, but not necessarily exciting.

Resources and impactful experiences

The makerspace and the makerspace staff! We would not have succeeded without the great atmosphere that was down in the IC. I still play Minecraft every now and then with some of the staff even though none of us have worked at the IC for years.

[The Innevation Center offered] a great learning experience and a place I remember fondly, even if I had very little sleep or free time throughout the two or so years I worked on my startup there.

Looking ahead

I think it would be really cool to see the capabilities of the Makerspace improve over time (I’m biased towards machining and grinding and whatnot, but it would be great to see improvements for makers of all types). It would also be great to see increased involvement from STEM students at the University. Somehow, I had no idea the IC existed until I was a junior.

Advice and encouragement

"If you have a project that you want to turn into a business – at least a technically focused one – you should probably estimate that everything will take ~10x longer than you expect."

I thought I would have a working prosthetic knee prototype with our artificial muscles in a month or two. It took two years. Getting our technology into real, market-ready prosthetic devices took ~4 years. Was still worth it though!

Try to pick the brains of the customers, engineers, researchers and clinicians in the industry you want to work in as soon as possible. You might realize the issues you think are the most pressing are irrelevant, and vice versa.