Responding to the national need for lithium-based batteries, Chemical & Materials Engineering Professor Mano Misra and his team this fall began working with industry to extract the metal in an environmentally sensitive way.

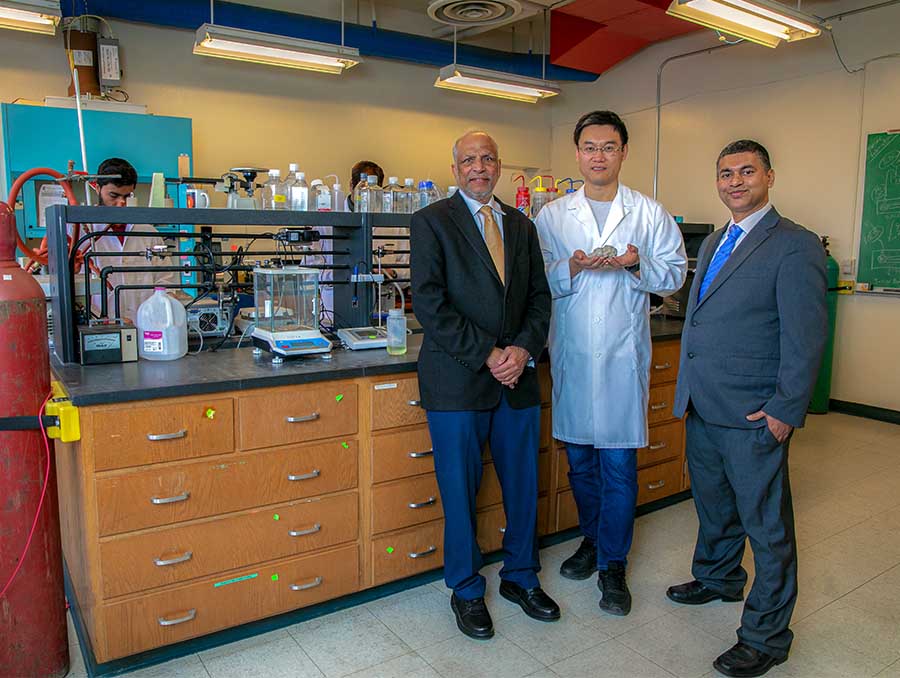

Misra, along with Mechanical Engineering Professor Pradeep Menezes and Mining and Metallurgical Engineering Professor Pengbo Chu, are working with American Battery Technology Company (ABTC) to develop a proprietary, low-environmental-impact process that ultimately would be employed to extract 5,000 tons of lithium hydroxide yearly from a commercial facility in Nevada’s Smoky Valley, near Tonopah. The project involves characterization, process engineering and modeling to optimize a lithium extraction process that needs less water and less energy, and will produce less waste.

“We have to develop a process that is environmentally acceptable and energy efficient,” Misra said.

Misra and graduate students have developed a new, low-temperature, alkaline salt roasting process to extract lithium from lithium-bearing clays as well as from difficult-to-process hectorites (a relatively rare, naturally occurring clay.) They currently are in the process of optimizing the technology.

Initial funding for the $4.5 million, three-year project recently was released to Misra and team.

A regional lithium economy

Misra’s project is one of several lithium research efforts underway at the University, as it works to develop a regional economy based on lithium.

- Chu — who is working with Misra on the extraction project — has a project with Lithium Americas to mitigate the company’s carbon emissions.

- The University’s Research & Innovation department earlier this year received a $1 million National Science Foundation Type-1 Engine award to develop an economic ecosystem around the lithium lifestyle.

- And earlier this month, the University was named one of 31 Regional Technology and Innovation Hubs (Tech Hubs) by the U.S. Department of Commerce’s Economic Development Administration. The Nevada Lithium Batteries and Other EV Material Loop (“Loop Tech Hub”) aims to build a self-sustaining and globally competitive full lithium lifecycle ecosystem.

“The College of Engineering will work with the College of Science to train skilled workers,” Misra wrote. “Diversity, equity and inclusion is a critical component of the project. This project will have resources for training and education of students from underrepresented groups, particularly from the indigenous tribes.”

Driving those projects is the national goal to establish a domestic supply chain for lithium-based batteries as laid out by the U.S. Department of Energy (DOE) in its June 2021 National Blueprint for Lithium Batteries and subsequent federal funding for those projects through the 2021 Bipartisan Infrastructure Law.

And, of course, the fact that Nevada has vast amounts of lithium locked inside its sedimentary clays.

The College of Engineering is committed: one of its research pillars is resilient lithium supply chains and critical materials.