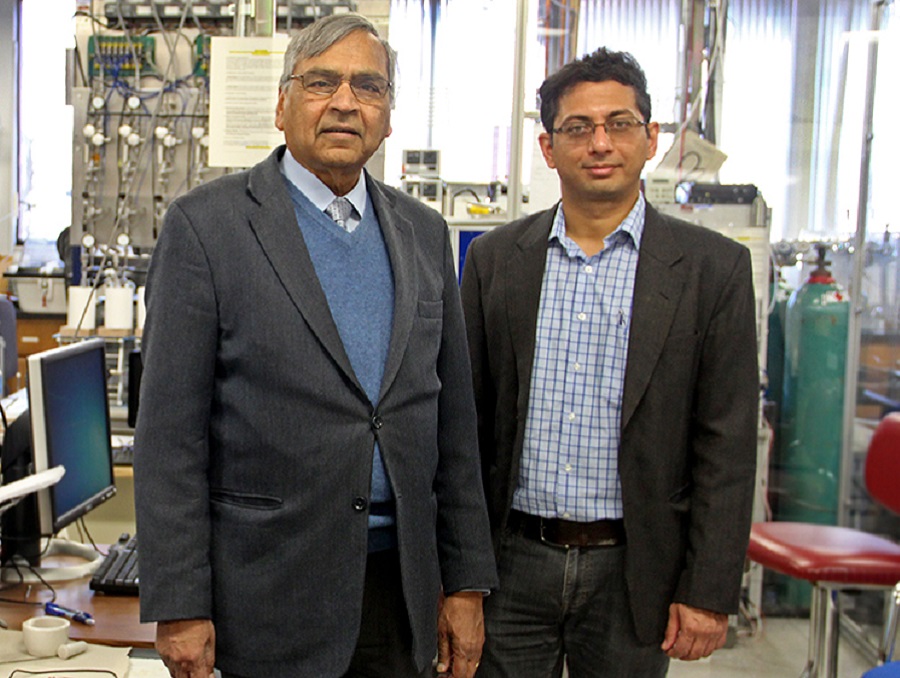

Sid Pathak, assistant professor of chemical and materials engineering, was awarded a grant from the U.S. Army Research Office for his collaborative research with the Colorado School of Mines. Working with associate professor of mechanical engineering, Garritt Tucker, the project, titled “Mechanistic-Design of Multilayered Nanocomposites: Hierarchical Metal-MAX Materials for Tunable Strength and Toughness,” focuses on how multilayered materials have useful mechanical, chemical and functional properties. These can be useful when tested in wide ranges of temperature, mechanical loadings and environmental conditions.

Nanocomposites are a class of composite materials where the size of the base or constituent materials are on the nanoscale - one nanometer being one-billionth of a meter. They can offer unprecedented properties beyond those currently studied and used. Their adaptations can be used for armor, for example, or a better protective coating for military equipment.

The objectives for the research are to design and synthesize multi-layered nanocomposites composed of alternating metallic and MAX phase layers with a thin, flat layer, or lamellar thickness reduced to the nanoscale. The MAX phases are layered, hexagonal carbides and nitrides. These carbides and nitrides possess an unusual combination of chemical, physical, electrical, and mechanical properties, exhibiting both metallic and ceramic characteristics, such as high electrical and thermal conductivity, thermal shock resistance, damage tolerance, and machinability.

This work is an integrated experimental and computational research partnership between UNR and Mines. Pathak will utilize the state-of-the-art reach equipment in his laboratory at the University to design these Metal-MAX multilayers and establish a fundamental understanding of their hierarchical interface driven microstructure and microstructure-property relationships. These results will be used to inform the atomistic computational modeling and simulations being conducted at Mines by Tucker.