Making a new material is one thing, explaining how you did it is another.

Materials engineering Ph.D. candidate Jerry Howard excels at both.

Howard developed a new “recipe” for making metallic glass and then explained the process at the Graduate’s School’s 3-Minute Thesis competition last spring, winning first place in the Ph.D. category.

“Giving a three-minute talk is much more difficult than giving a three-hour talk,” Howard said.

Especially when your topic is very technical, like metallic glass.

Metallic glass

Metallic glass is metal that is cooled so quickly that it doesn’t form crystals, like metals typically do. Instead, metallic glass has a disordered structure that gives the material exceptional strength and corrosion resistance.

“This unique structure enables metallic glasses to have very high strength, as well as resistance to radiation and corrosion or rust,” Howard stated in his 3-Minute Thesis presentation.

Materials this durable are necessary to make equipment that can operate in harsh environments, such as space or in nuclear reactors. These materials will enable the technologies that can protect lives, expand our knowledge, and help solve global problems.

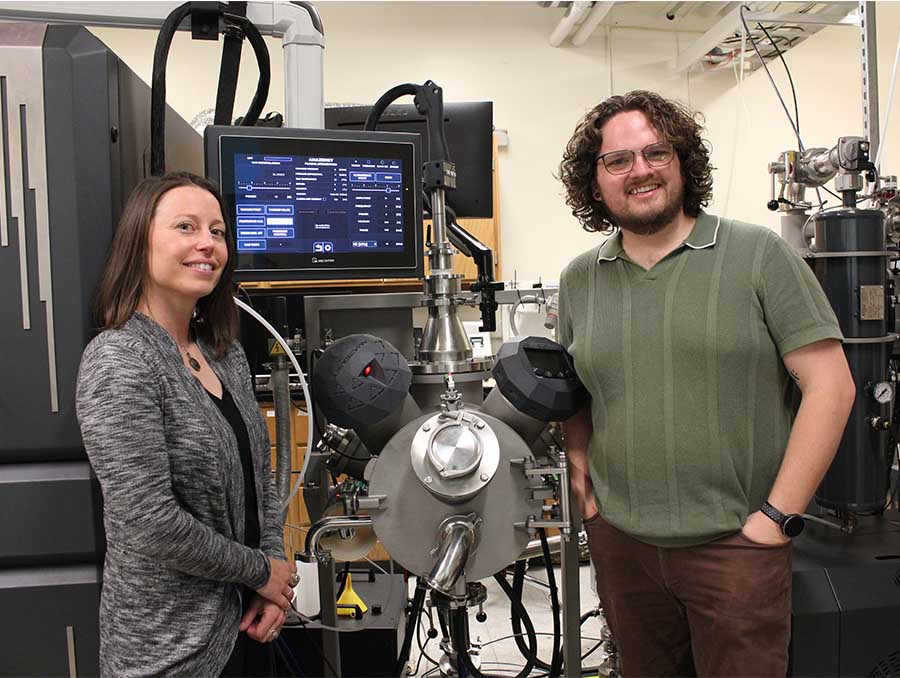

Howard’s Ph.D. advisor, Chemical & Materials Engineering Associate Professor Krista Carlson, is conducting research in this area of materials science.

“I was wondering whether the unique moldability of glass when hot could be used to form a dense, bulk piece that would otherwise crystallize with conventional processing,” Carlson said. “Producing metal parts for harsh environments is challenging in itself. Creating bulk glassy versions is even harder but one that is well worth pursuing.”

Others think so too: Carlson has received funding from the U.S. Department of the Air Force (award FA9550-22-1-0363) and the Office of Naval Research (contract number N000142412341) to support this work.

“In recent years, we’ve gathered and contributed to the design of specialized synthesis and characterization equipment that is rare among institutions,” Carlson said. “And it’s part of what makes our materials science program stand out.”

6,192 degrees Fahrenheit

Howard is working on a new recipe for making metallic glass to solve a problem that occurs when metallic glass is produced with a 3D-printer. 3D-printing is important, Howard said, as it is one of the only ways we might be able to make large pieces metallic glass for structural applications.

To 3D print with a metal, Howard explained, you have to start with metal powder.

The process begins with melting a metal, and Howard and Carlson are working with some of the most difficult to melt: tungsten, which has a melting point of about 6,192 degrees Fahrenheit, and tantalum, which has a melting point of 5,463 degrees Fahrenheit.

“Because they melt at such high temperatures, we have to use exotic ways to melt them,” Howard said. In this case, a plasma torch is used in an inert atmosphere — an environment where reactive gas has been minimized or removed.

Once melted, an ultrasonic atomizer is used to turn the liquid into fine droplets that are cooled rapidly — and by rapidly, Howard means as high as 1 million degrees Celsius per second — to create metallic glass powder.

The metallic glass powder then goes into a 3D printer, where it’s selectively melted by a laser to form a thin layer of metallic glass.

What makes it a glass and not just thin layer of metal?

The atomic structure.

In regular metal, atoms are arranged in a highly ordered, crystalline pattern. In glass, including metallic glass, atoms are disorganized. This is the same structure that exists in window glass, but in this case, is made using only metal atoms. This disordered structure gives metallic glass the corrosion resistance of glass as well as the strength and elasticity of metal.

So what’s the problem?

The problem is the heat from the laser in the 3D printer.

The metallic glass is printed layer by thin layer, theoretically allowing the glass structure to be maintained. However, overheating from the laser will cause previously printed layers to form small crystals, ruining the metallic glass.

Or maybe not.

Have you ever had an experience where what you initially thought was a weakness turned out to be a strength?

Howard asked this question in his three-minute thesis, because that’s what had happened in the lab.

“I chose to lean into the perceived weakness of unavoidable crystal formation,” he said.

Through computer modelling and experimentation, he came up with a recipe for new metallic glasses in which the crystals improve performance rather than harming it.

“This means I can use 3D printing to produce large metallic glass parts for use in the extreme environments … without worrying about small crystals,” Howard stated.

Breaking it down

Howard expects to complete his Ph.D. in materials science within the year. After graduation, he hopes to continue in academia as a researcher in the field of metallurgy, the study of metals and their alloys. He earned his bachelor’s degree in metallurgy at the University of Utah, where he worked for Carlson, who was on the faculty at that time. After receiving the highly competitive National Science Foundation Graduate Research Fellowship Program award, Howard joined the University of Nevada, Reno and works with Carlson and co-advisor Professor Dev Chidambaram, also in the Department of Chemical & Materials Engineering.

“Jerry is one of the best students I’ve had the pleasure of working with – he is a great researcher and mentor to incoming students. I am excited to continue our collaboration on advancing these materials.” Carlson shared.

While he hopes their work will advance scientific knowledge — “the whole thing about ‘science being built on the shoulders of giants,’ I take that very seriously,” he said — he also is committed to supporting the next generation of engineers.

And that starts with explaining technical topics for a general audience.

“Any student that comes in starts off as ‘general audience,’” Howard said. “That’s a very important thing to me: how do we get that student to where they can be an engineer or a scientist.”